0102030405

WC-10Co4Cr HVOF/HVAF thermal spray powder Excellent abrasion resistance

Basic parameters

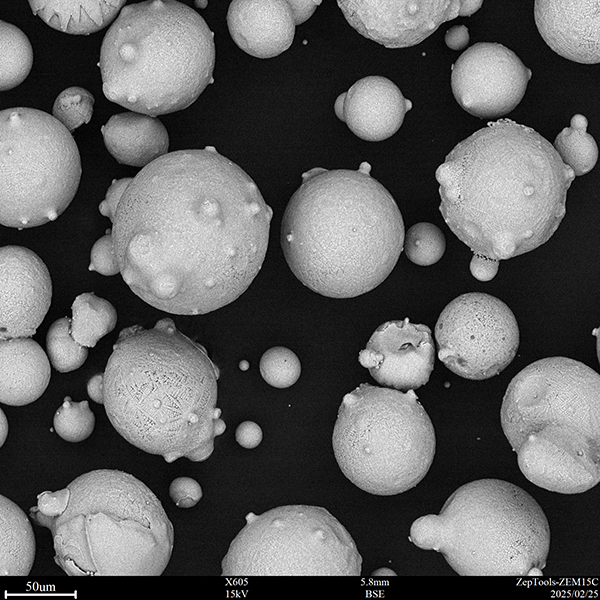

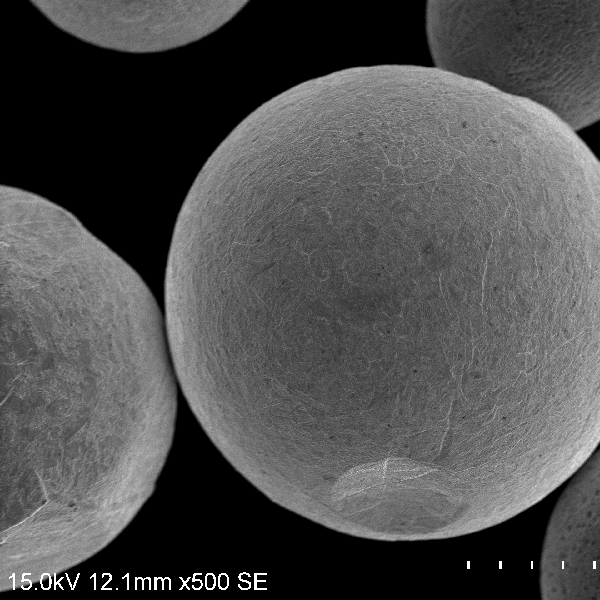

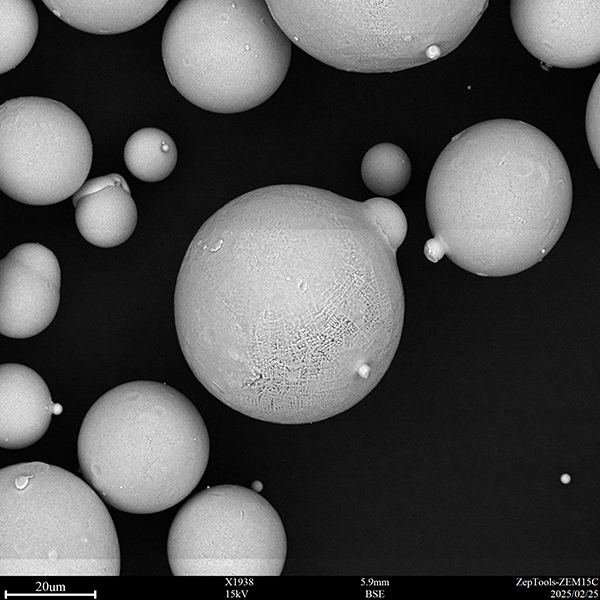

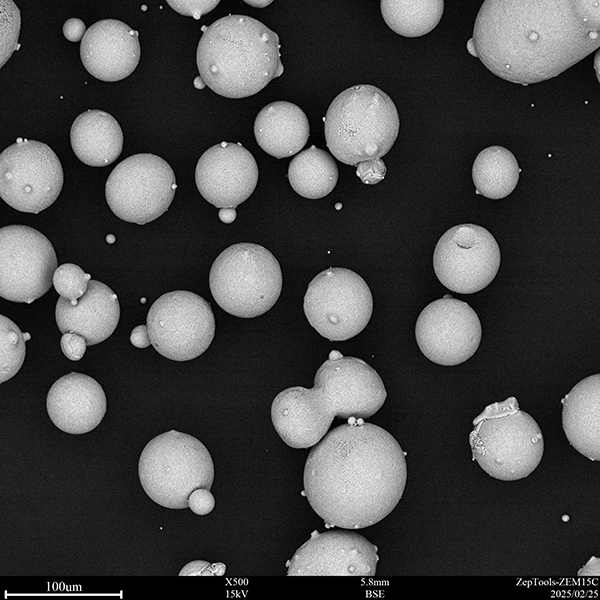

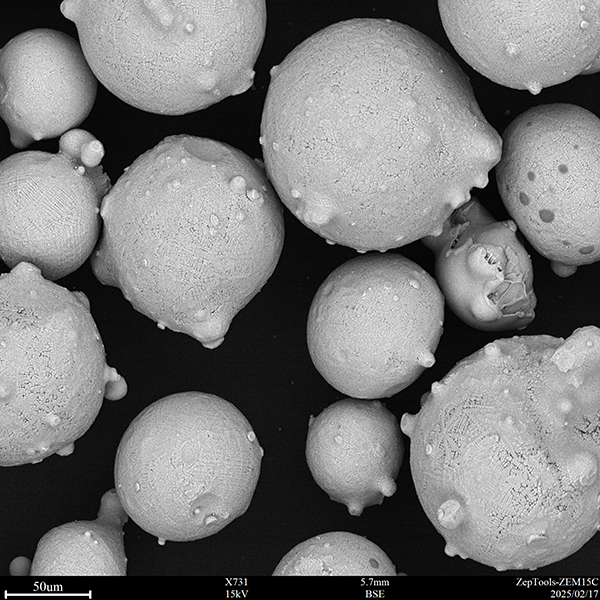

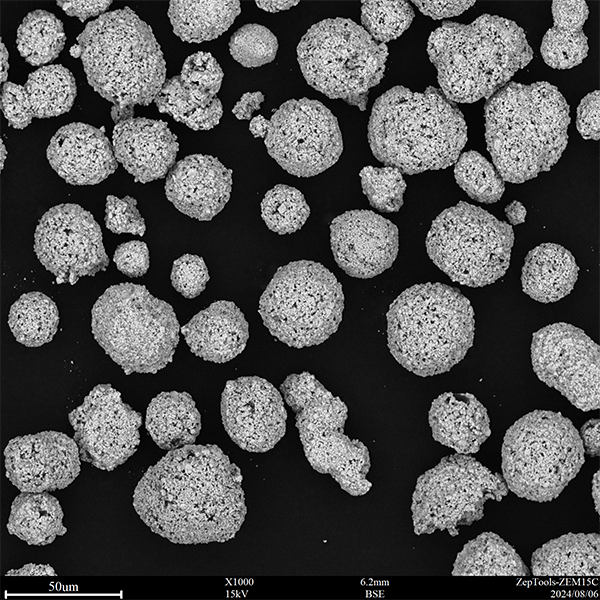

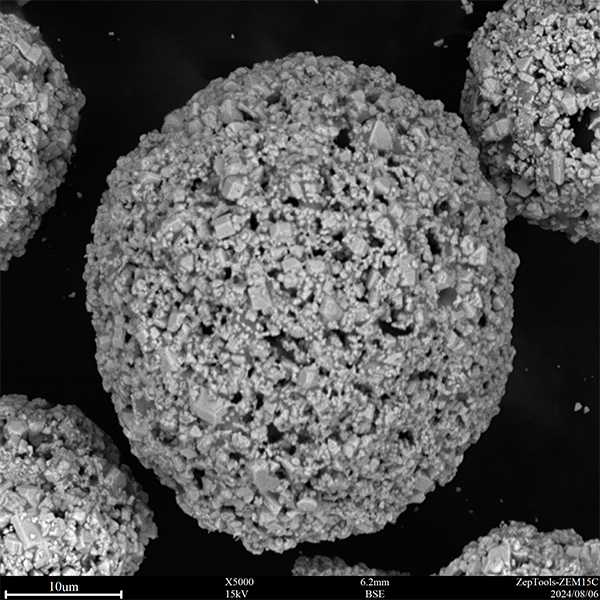

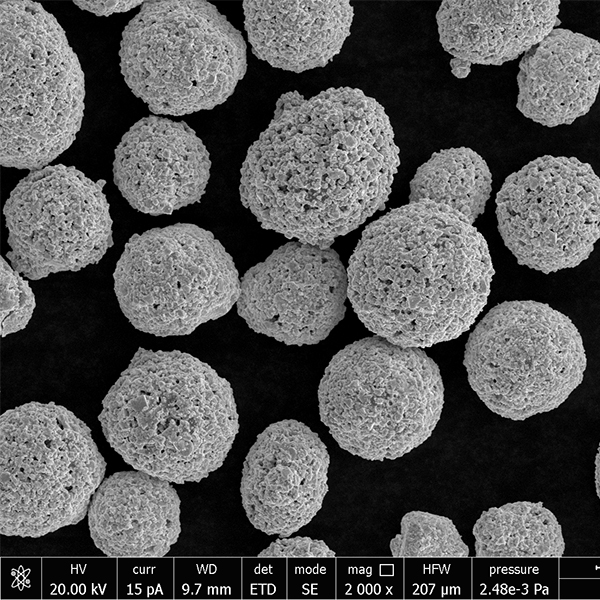

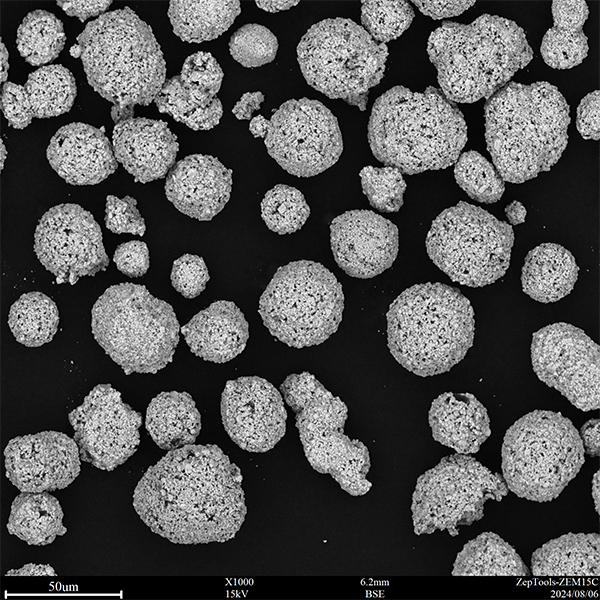

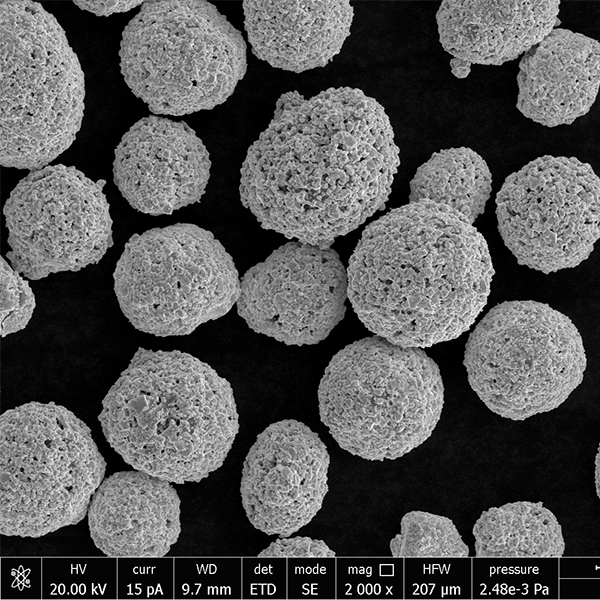

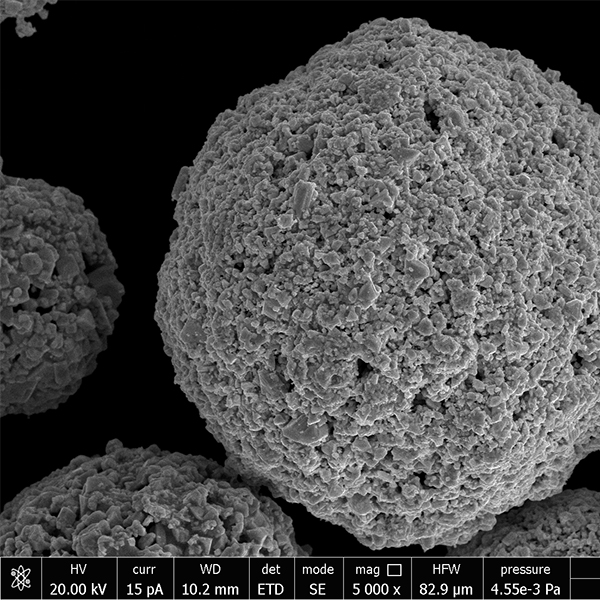

The chemical composition of DG.WC-10Co4Cr is 9.5% carbon, 10% cobalt, 4% chromium and the balance tungsten. This combination not only improves the hardness of the coating, but also enhances its wear and corrosion resistance. The powder is produced using agglomeration sintering process, which ensures its uniformity and stability. Its Vickers hardness ranges between 1200 and 1400 HV, showing its excellent hardness characteristics.

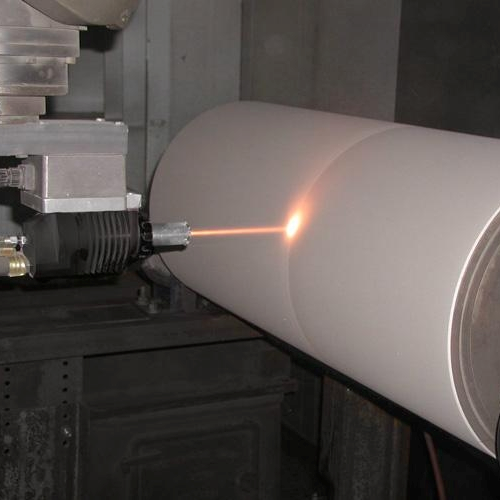

In terms of thermal spraying process, DG.WC-10Co4Cr is suitable for a variety of processes such as high temperature flame spraying (HVOF), high pressure air flame spraying (HVAF) and plasma spraying (APS). These processes can effectively deposit the powder coating onto the substrate surface to form a strong coating. The bonding strength exceeds 70MPa, the porosity is less than 0.8%, and the deposition rate is between 48% and 55%, showing its excellent coating quality.

Product Performance

The performance characteristics of DG.WC-10Co4Cr make it widely applicable in industrial applications. First, its wear and corrosion resistance are very good, and it can maintain good performance in harsh environments. Secondly, the high bonding strength of the coating ensures a strong bond between the coating and the substrate, avoiding the risk of coating peeling. In addition, the material also has high impact toughness and can withstand large impact forces, making it suitable for occasions with high impact loads.

DG.WC-10Co4Cr is particularly outstanding in terms of sliding wear resistance and is suitable for parts that require frequent friction, such as valve seats, various rollers, and compressor blades. Its high deposition rate allows the coating to be deposited in a relatively short period of time, thus improving production efficiency.

Spraying process parameters

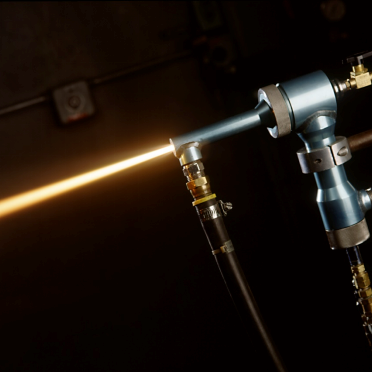

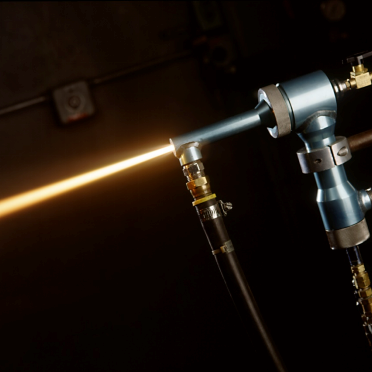

In terms of spraying technology, the spray gun model of DG.WC-10Co4Cr is Lijia kerosene supersonic spray gun, and the powder particle size is 15-45um. During the spraying process, the kerosene consumption is 23L/h, the oxygen flow rate is 900L/min, the carrier gas flow rate is 8.0L/min, the powder feeding speed is 70-80g/min, and the spraying distance is between 320-360mm. It should be noted that the above parameters are for reference only, and the specific spraying parameters may be adjusted depending on the equipment.

Application Areas

DG.WC-10Co4Cr is widely used in the manufacture of various wear-resistant parts, especially in the petroleum, chemical, metallurgical and other industries, which can effectively improve the durability and reliability of equipment. By using DG.WC-10Co4Cr coating, enterprises can significantly reduce the maintenance frequency and replacement cost of equipment, thereby improving overall production efficiency.

In conclusion, DG.WC-10Co4Cr thermal spray powder has become an indispensable and important material in modern industry due to its excellent performance and broad application prospects.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.