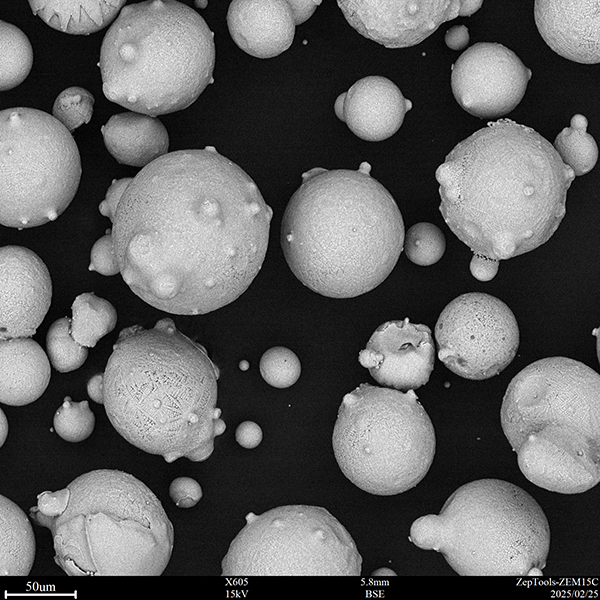

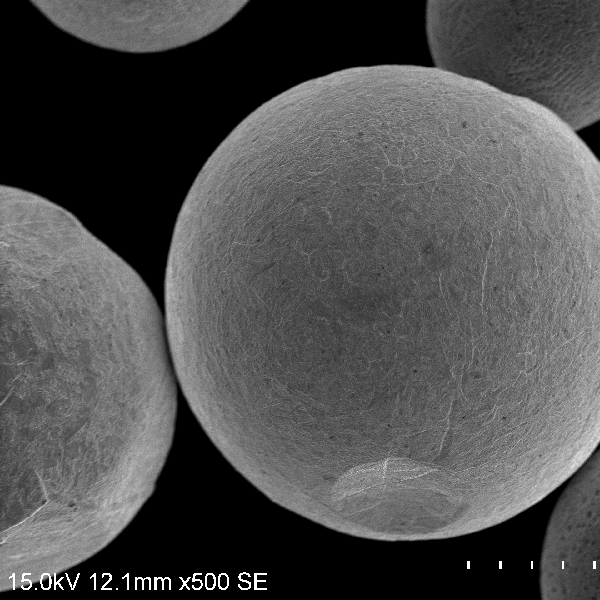

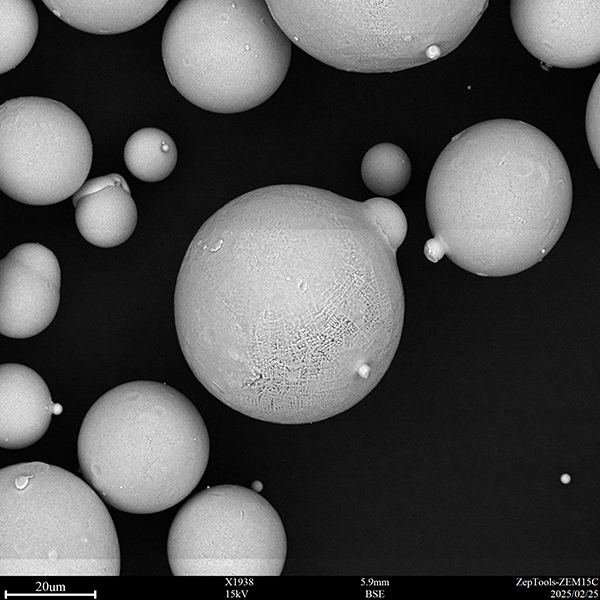

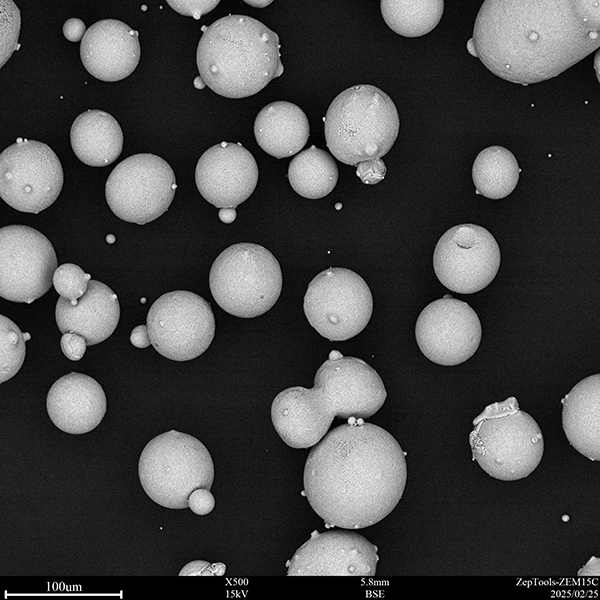

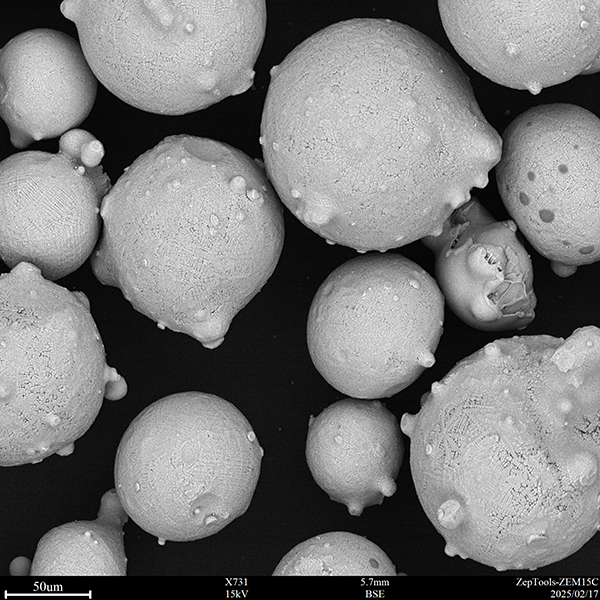

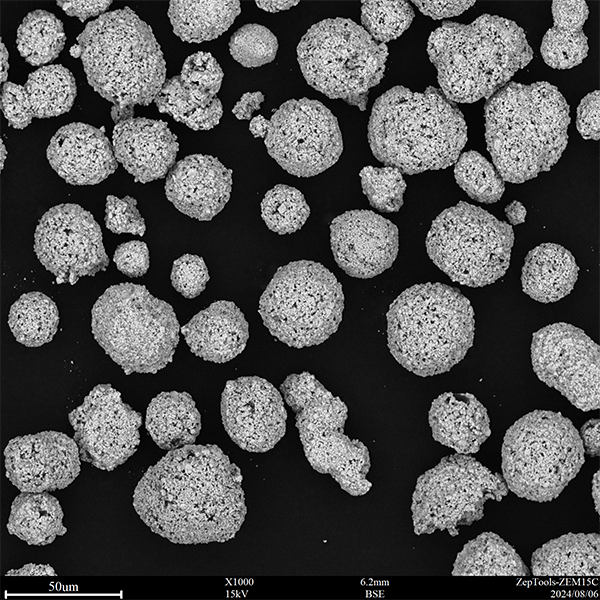

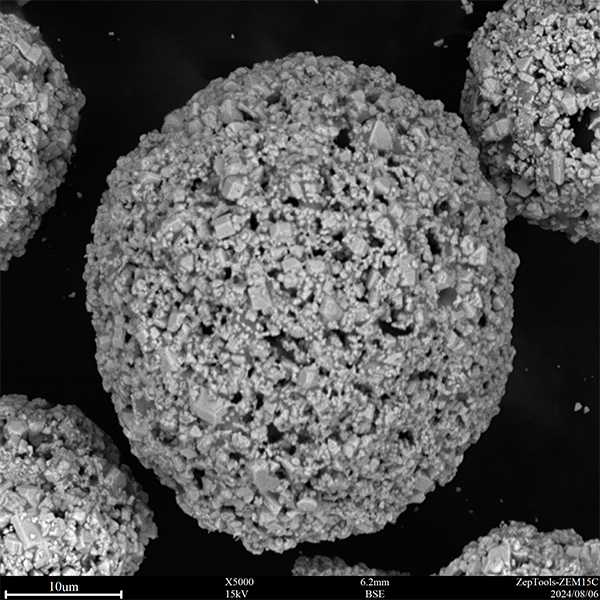

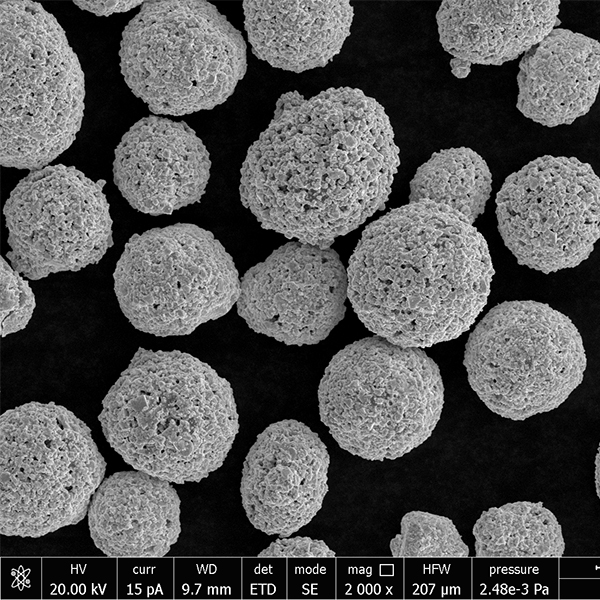

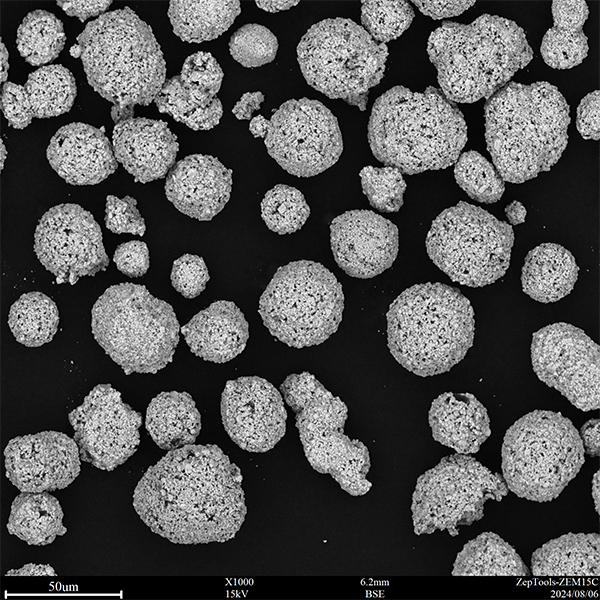

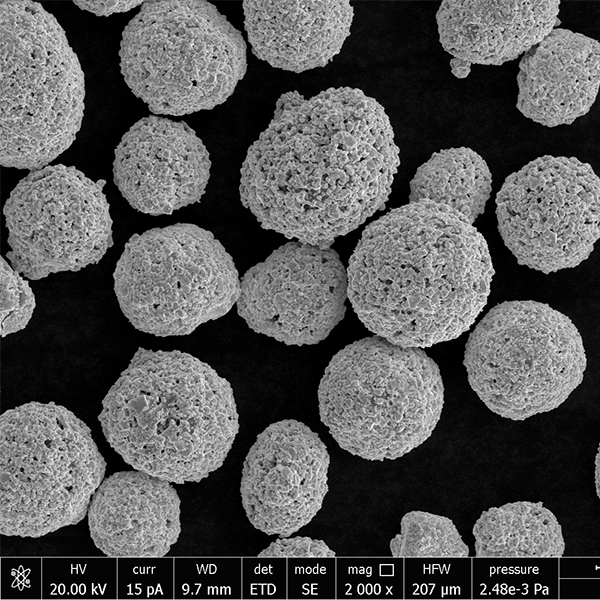

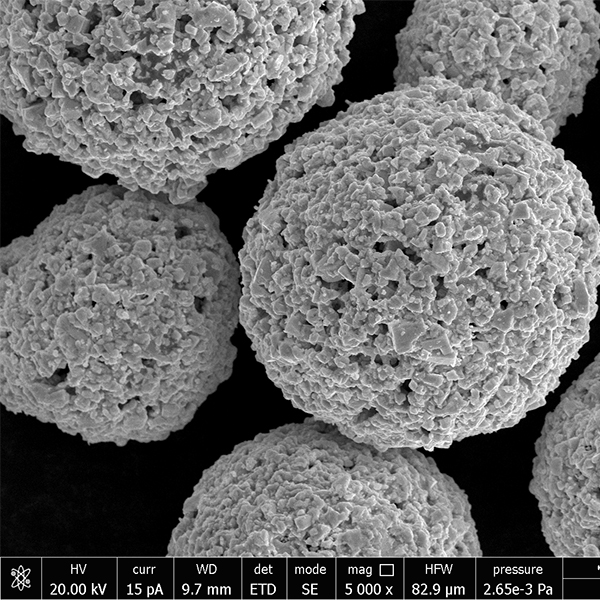

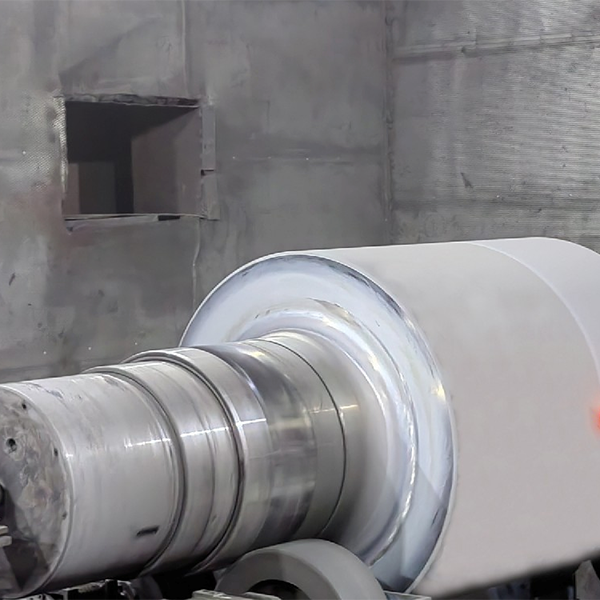

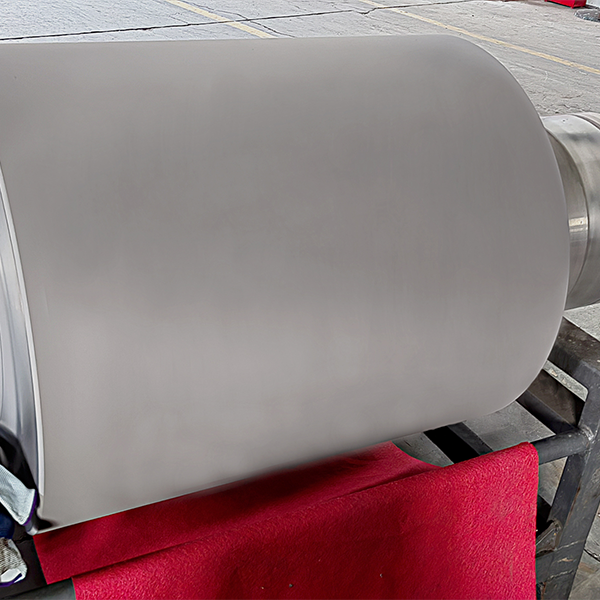

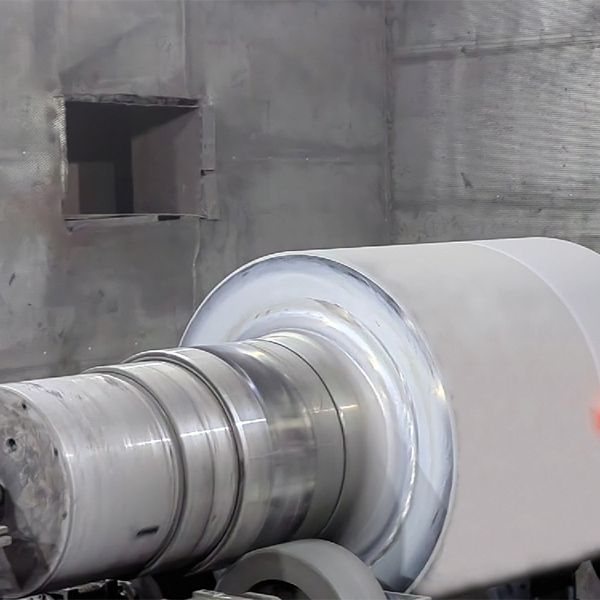

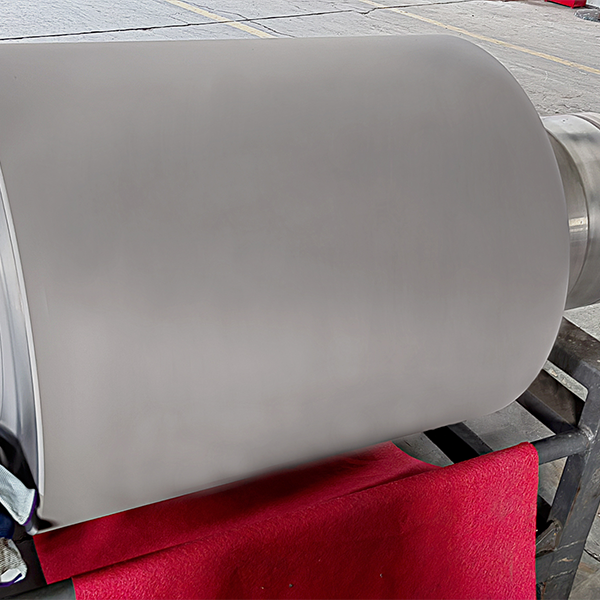

WC-12Co HVOF/HVAF thermal spray powder Excellent abrasion resistance

Performance characteristics

Typical Applications

Notes

Although DG.WC-12Co performs well in many applications, it is not recommended for use in acidic environments. To achieve better corrosion resistance with comparable wear resistance, powders such as WC 10Co 4Cr or WC 20CrC 7Ni are recommended. These alternative materials offer improved performance in specific environments.

In Conclusion

DG.WC-12Co is an ideal thermal spray powder. With its excellent performance and wide application fields, it has become the preferred material in the industry. Whether in high temperature, high wear environment, or in applications requiring high corrosion resistance, DG.WC-12Co can provide reliable solutions to help companies improve production efficiency and reduce operating costs. Choosing DG.WC-12Co, you will get excellent surface protection and lasting performance guarantee.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.