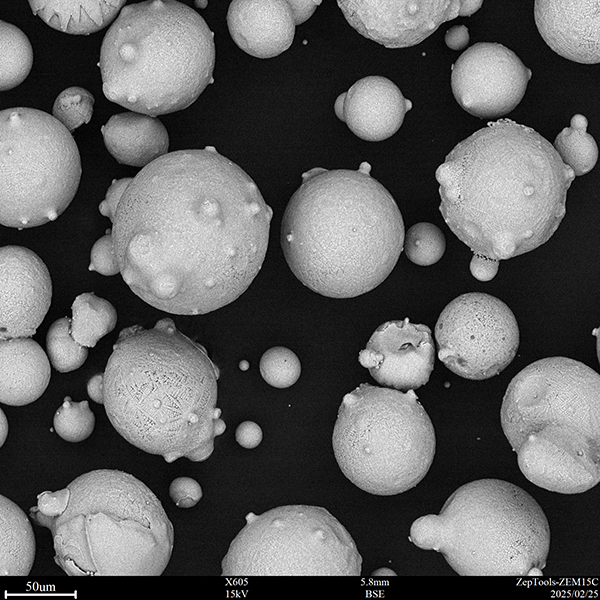

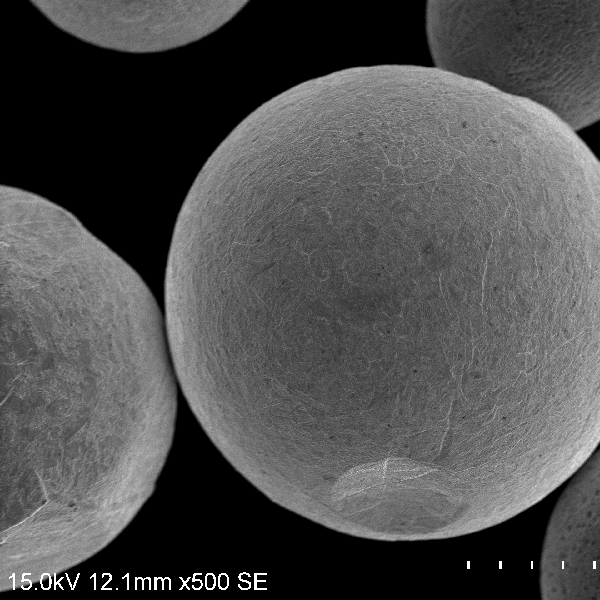

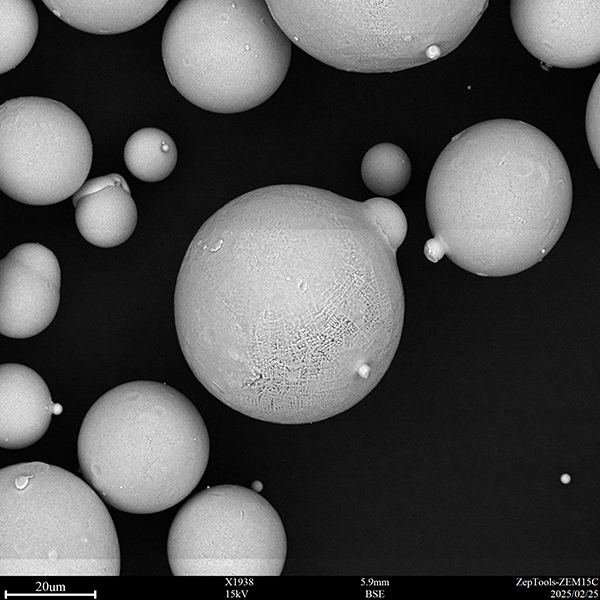

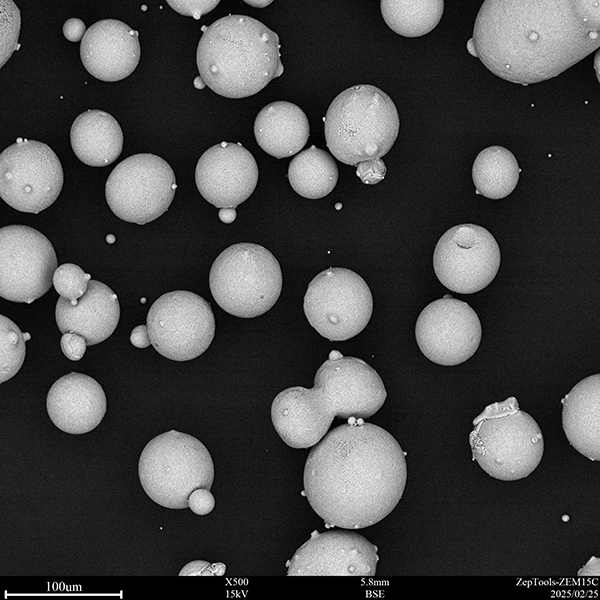

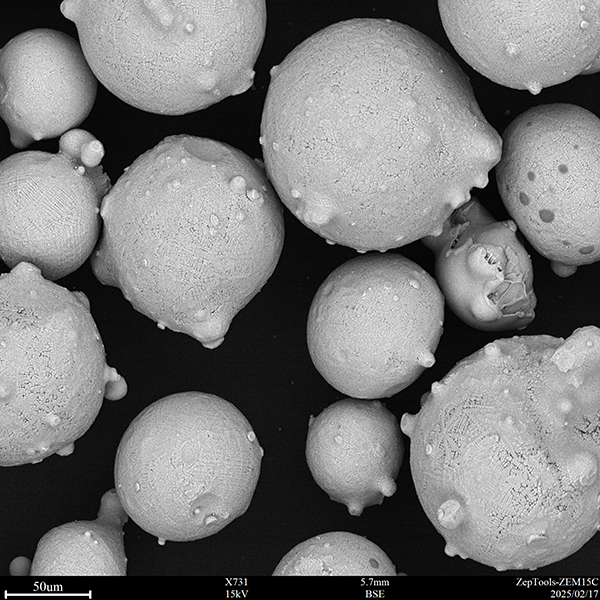

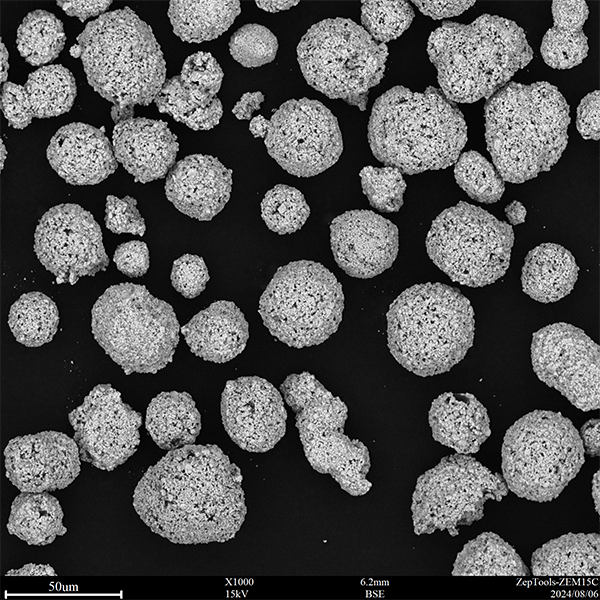

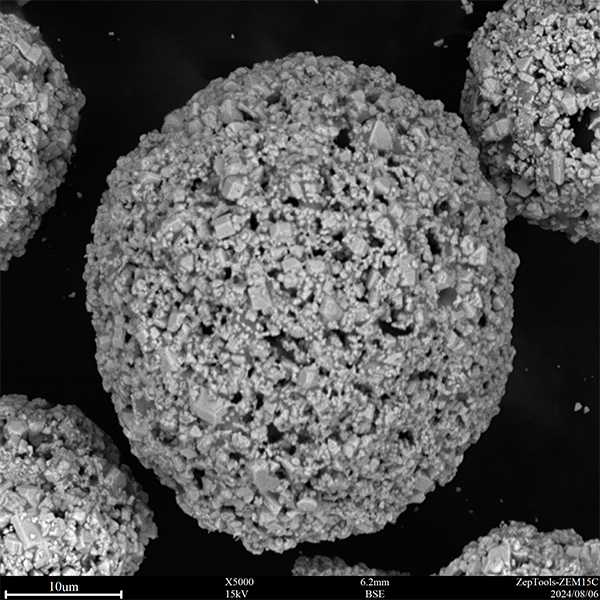

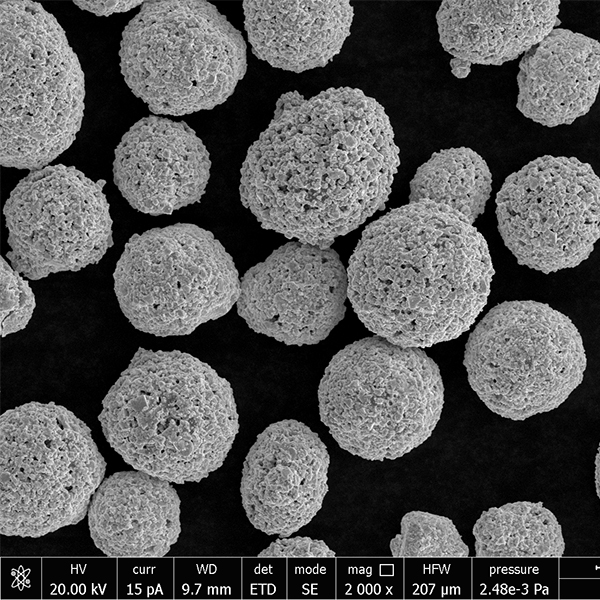

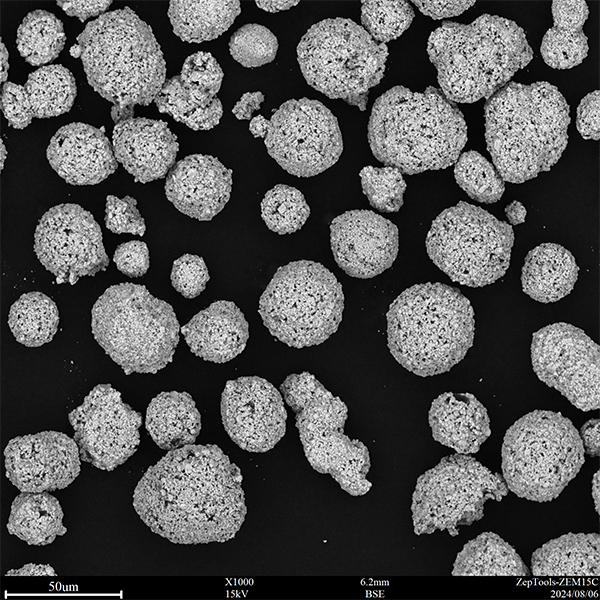

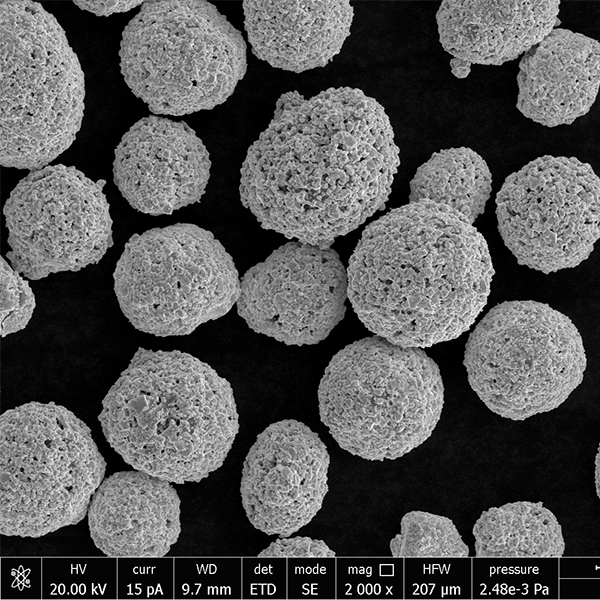

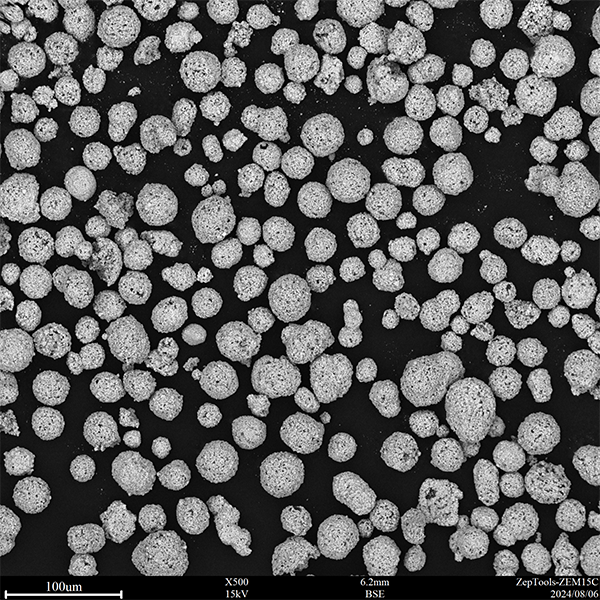

WC-12Ni HVOF/HVAF thermal spray powder, Suitable for wet working environments

Basic parameters

Product performance

Application Areas

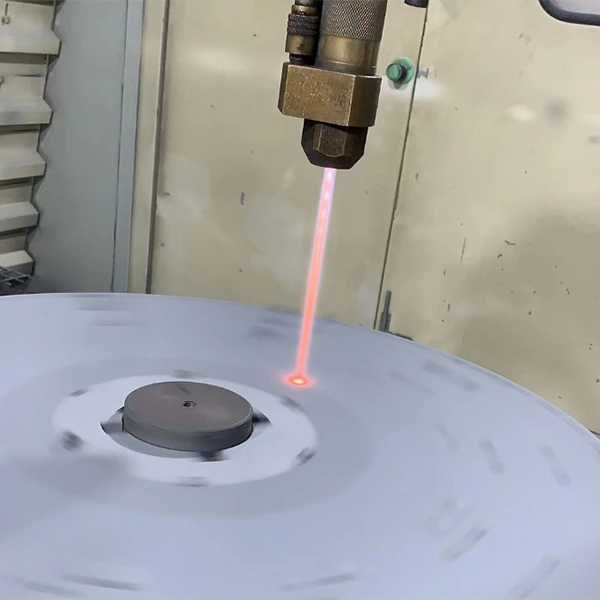

DG.WC-Ni12 powder has a wide range of applications, especially in the chemical industry. Due to its excellent wear resistance and corrosion resistance, it has become the first choice material for many equipment. In marine engineering, equipment often faces harsh environmental conditions. The high temperature tolerance and non-magnetic characteristics of DG.WC-Ni12 make it widely used in offshore oil exploration and heavy industry. In addition, with the development of industrial automation and intelligence, DG.WC-Ni12 has gradually been used in various high-end mechanical equipment and precision instruments.

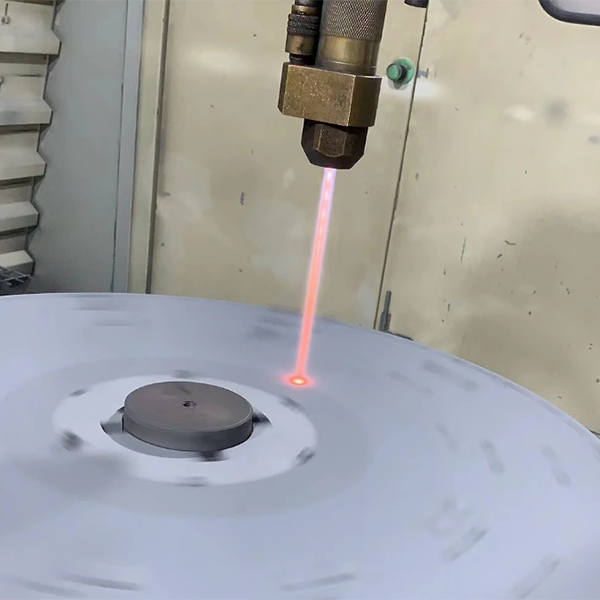

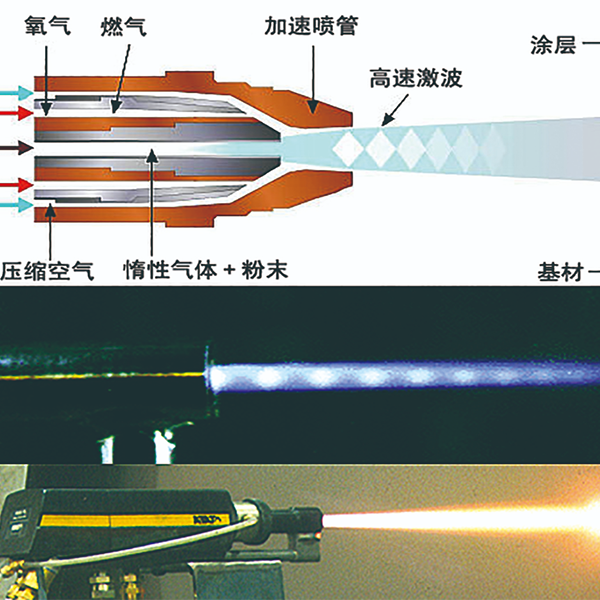

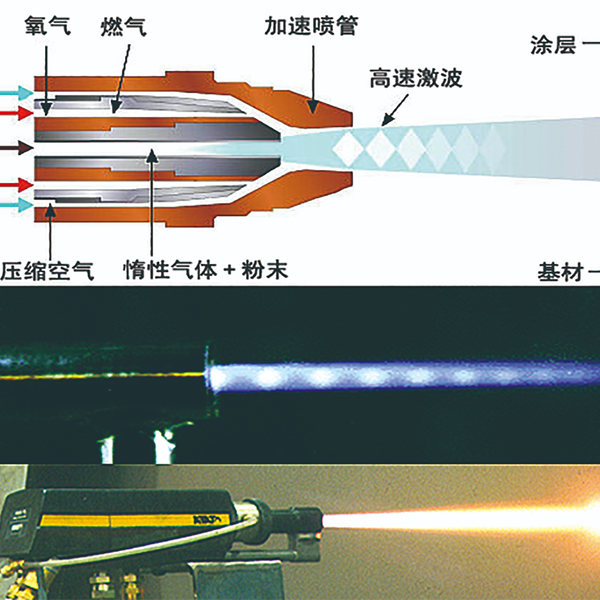

Spraying process parameters

During the spraying process, it is crucial to select the appropriate spray gun and process parameters. Taking the Lijia kerosene type supersonic spray gun as an example, the powder particle size is selected from 15-45um, the barrel size is 4 inches, the kerosene consumption is 24L/h, the oxygen flow is 900L/min, and the carrier gas flow is 8.5L/min. The powder speed is between 80-100g/min, and the spraying distance is 340-380mm. These parameters are for reference only. In actual operation, they need to be adjusted accordingly according to different equipment to achieve the best spraying effect.

In short, DG.WC-Ni12 thermal spray powder is becoming an important material in the field of surface treatment due to its excellent performance and wide application prospects. With the continuous advancement of technology and the continuous expansion of application fields, DG.WC-Ni12 will bring higher value and benefits to more industries.

What to know about this product?

SEND A MESSAGE

Something isn't Clear?

Feel free to contact me, and l will be morethan happy to answer all of your questions.